Let's Talk !

Supply chain management (SCM) is one of the most complex facets of the production process. Every aspect of your supply chain needs to operate in harmony to produce high-quality products. Keeping track of the multitude of factors involved can be overwhelming and time-consuming.

Predictive maintenance solutions are tools that manufacturers can use to determine when critical machinery in their supply chains will fail or need maintenance ahead of time. In this overview, we'll explain how the ever-evolving arena of the Internet of Things (IoT) connectivity is making predictive maintenance in SCM easier and more accurate than ever before.

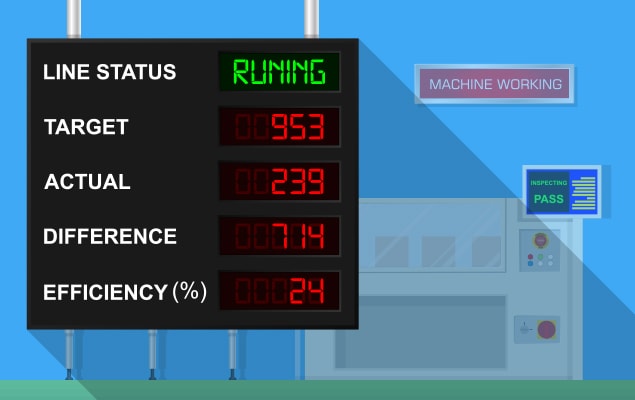

Predictive maintenance technologies allow manufacturers to remain aware of the status of their equipment at all times. These technologies are installed on or near pieces of manufacturing equipment, and they provide real-time data on the efficiency of equipment and the necessity of maintenance intervention.

Various internet-connected sensor devices monitor the status of production equipment. Some examples of these preventive maintenance technologies include thermal sensors, which monitor the heat that a piece of equipment emits, and sonic sensors, which test for changes in the sounds emitted by equipment.

Other IoT preventive maintenance tools monitor the vibration that production equipment emits for anomalies. All of these different types of preventive maintenance technologies feed the data they collect to central software systems that use algorithmic functions to predict when maintenance will be necessary.

CMMS software helps manufacturers keep track of the maintenance schedules for their production equipment. This type of software varies in complexity, and older CMMS solutions may require more manual input.

In recent years, however, CMMS software has evolved to handle input from IoT devices. Advanced CMMS software can now monitor the status of dozens of different pieces of equipment and use complicated algorithms to deliver clear, actionable insights regarding ideal preventive maintenance procedures. Some of the key functionalities of CMMS software include:

CMMS software facilitates the communication between IoT devices and central servers that is necessary to provide real-time data on the current status of production equipment. Data storage mines collected data from IoT devices in centralized, secure locations for easy reference and categorization. Most importantly, CMMS software provides actionable Data analytics that manufacturers can use to develop effective preventive maintenance procedures.

CMMS software is the central hub that connects all the information provided by IoT preventive maintenance tools and makes this data easy for manufacturers to access and use. To accomplish this task, CMMS software uses highly complex condition-based algorithms to assess the condition of production equipment and develop plans for preventive maintenance. Predictive maintenance software uses these algorithms to leverage both real-time and stored data to predict when equipment will fail or require maintenance. Then, before any equipment failure actually happens, CMMS software delivers analytics that allows preventive maintenance to take place. CMMS software can provide these algorithmic insights for dozens of pieces of equipment simultaneously.

In the past, equipment failures required the complete or partial shutdown of production while maintenance occurred. This inevitable inefficiency naturally slowed down production and reduced profits, but manufacturers were forced to accept unexpected equipment failure as a cost of business.

With predictive maintenance, however, it's possible to address equipment that is expected to become faulty at ideal times that do not conflict with production schedules. This revolution in supply chain software efficiently allows manufacturers to anticipate production delays well in advance. This keeps the supply chain operating effectively without loss in either production volume or revenue.

IoT devices that predict when equipment will fail or need maintenance, however, are only as good as the software that collects, stores, and analyzes the data they provide. Custom CMMS is the best software solution for manufacturers since it provides the flexibility necessary to adapt to your unique circumstances. Invest in custom predictive maintenance software to improve productivity and avoid setbacks.

Disclaimer:

Chetu, Inc. does not affect the opinion of this article. Any mention of specific names for software, companies or individuals does not constitute an endorsement from either party unless otherwise specified. All case studies and blogs are written with the full cooperation, knowledge and participation of the individuals mentioned. This blog should not be construed as legal advice.

Chetu was incorporated in 2000 and is headquartered in Florida. We deliver World-Class Software Development Solutions serving entrepreneurs to Fortune 500 clients. Our services include process and systems design, package implementation, custom development, business intelligence and reporting, systems integration, as well as testing, maintenance and support. Chetu's expertise spans across the entire IT spectrum.

- See more at: www.chetu.com/blogs

Privacy Policy | Legal Policy | Careers | Sitemap | Referral | Contact Us

Copyright © 2000-2024 Chetu Inc. All Rights Reserved.